Working Principle and Structural Characteristics:

YK series circular vibrating screen is mainly composed of screen box, screen, vibrator and damping spring etc. Vibrator is installed on the screen box side plate, and is driven rotation by a motor through the coupling, generating centrifugal inertia force and forcing sieve box vibrate.

Screen mesh are the main easily damaged parts to this series of vibrating screen. According to the material varieties and user requirements, can use high manganese steel textile screen mesh, perforated screen plate and rubber sieve plate. Sieve plate has single layer and double layers. Each kind of sieve plate can meet requirments of high screening efficiency, long service life and no blocking screen.

This series of vibrating screen is seat type installation. Screen surface angle of inclination adjustment can be realized by changing the spring support position height. The motor is installed on the left of the screen frame, also can be installed on the right. If no special requirement, we will install it according to the right side of material movement direction.

Main Application:

This series of circular motion vibrating screen sieve box trajectory is round.

Suitable for screening coal, limestone, crushed stone, gravel, metal or non-metal ores and other materials.

And it has been widely used in coal dressing, mineral separation, building materials, water and electricity, light industry, construction and other departments for dry material classification.

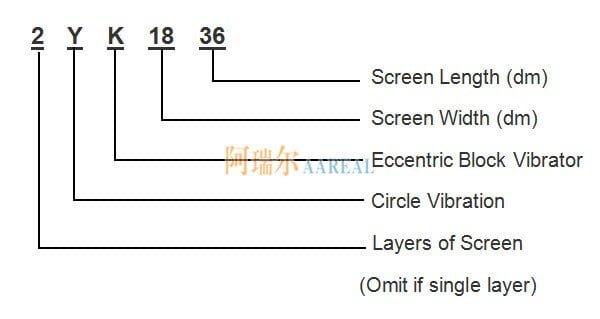

Model Number Definition:

Technical Parameter:

| Model | Screen Surface | Feed Size | Capacity (t/h) | Frequency | Double Amplitude | Motor | Each Fulcrum Dynamic Load | Weight (kg) | |||||||

| Layer | Area | Dip Angle | Sieve Mesh | Structure | Model | Power (KW) | At Work | Start & Stop | |||||||

| YK1430 | 1 | 4.2 | 15° | 3~100 | Perforated Plate, polyurethane | ≤200 | 18~375 | 970 | 7~10 | Y160M-6 | 7.5 | ±800 | ±6400 | 3612 | |

| YK1845 | 1 | 6 | 21~438 | 970 | Y180L-6 | 15 | ±1000 | ±8000 | 4664 | ||||||

| YK2050 | 1 | 8.1 | 23~479 | 970 | Y180L-6 | 15 | ±1200 | ±9600 | 5426 | ||||||

| YK2445 | 1 | 10.5 | 26~542 | 970 | Y200L-6 | 18.5 | ±1200 | ±9600 | 6232 | ||||||

| YK2450 | 1 | 12 | 31~646 | 970 | Y200L-6 | 22 | ±1800 | ±9600 | 7000 | ||||||

| YK2460 | 1 | 14.4 | 31~646 | 970 | Y225M-6 | 30 | ±1800 | ±14400 | 8490 | ||||||

| YK3060 | 1 | 18 | 39~813 | 980 | Y225M-6 | 30 | ±2400 | ±19200 | 10510 | ||||||

| YK3660 | 1 | 21.6 | 47~976 | 980 | Y250M-6 | 37 | ±4000 | ±32000 | 14900 | ||||||

| 2YK1430 | 2 | 4.2 | 18~375 | 970 | Y180L-6 | 15 | ±1200 | ±9600 | 5500 | ||||||

| 2YK1638 | 2 | 6 | 21~438 | 970 | Y200L-6 | 18.5 | ±1600 | ±12800 | 7000 | ||||||

| 2YK1845 | 2 | 8.1 | 23~479 | 970 | Y200L-6 | 22 | ±2000 | ±16000 | 8300 | ||||||

| 2YK2050 | 2 | 10 | 26~542 | 980 | Y225M-6 | 30 | ±2400 | ±19200 | 9800 | ||||||

| 2YK2450 | 2 | 12 | 31~646 | 980 | Y225M-6 | 30 | ±3200 | ±25600 | 10500 | ||||||

| 2YK2460 | 2 | 14.4 | 31~646 | 980 | Y225M-6 | 30 | ±3200 | ±25600 | 11210 | ||||||

| 2YK3060 | 2 | 18 | 31~646 | 980 | Y250M-6 | 37 | ±4400 | ±35200 | 15800 | ||||||

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

Mobile Phone/WhatsApp/WeChat: 0086-15637361027