Overview:

Powerful Rotary Vibrating Screen for Flour is also called flour gyratory screen,flour gyratory sifter,flour gyratory separator,flour screening machine,flour sieving machine,flour screening equipment,flour sieving equipment,flour vibrating sieve,flour vibrating screen,flour vibrating separator,flour vibro sieve,flour vibro screen,flour gyro screen,flour gyro sieve,flour vibro grader,flour sizer,flour grader,flour classifier,gyratory screen for flour,gyratory sifter for flour,gyratory separator for flour,screening machine for flour,sieving machine for flour,screening equipment for flour,sieving equipment for flour,vibrating sieve for flour,vibrating screen for flour,vibrating separator for flour,vibro sieve for flour,vibro screen for flour,gyro screen for flour,gyro sieve for flour,vibro grader for flour,sizer for flour,grader for flour,classifier for flour

Characteristics:

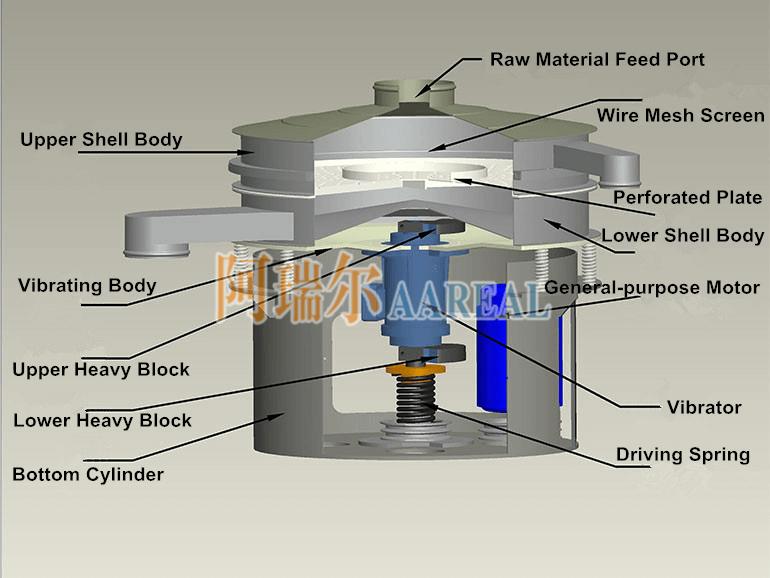

1. the longitudinal acceleration is twice as much as the original product rotary sieve (compared with our company)

2. the handling capacity is 2~4 times that of the original product (compared with our company). Materials those are difficult to screen can hardly clog up the mesh, and the output is also doubled.

3. the noise is obviously decreased. Small volume, convenient movement, no installation foundation

4. with more powerful vibration force and solid structure

5. more convenient to replace screen mesh

6. ordinary motor drive. Explosion-proof motor drive is also available

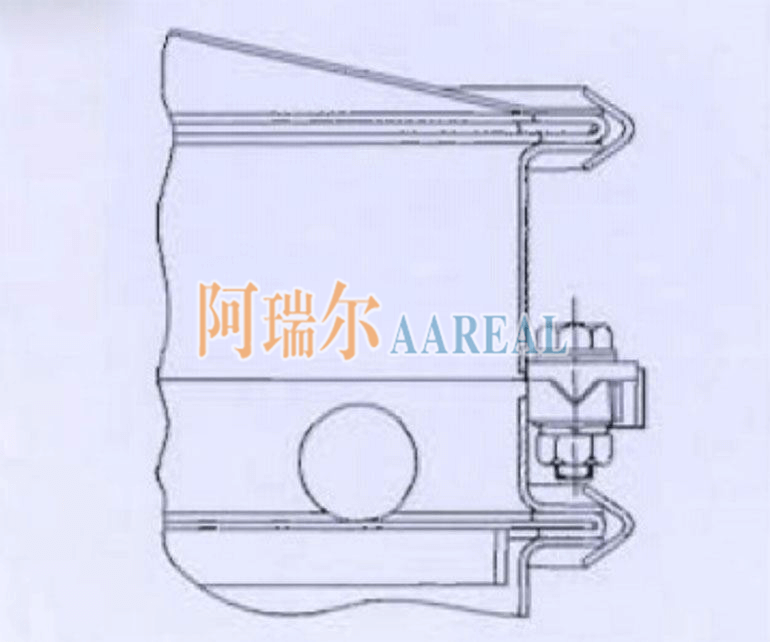

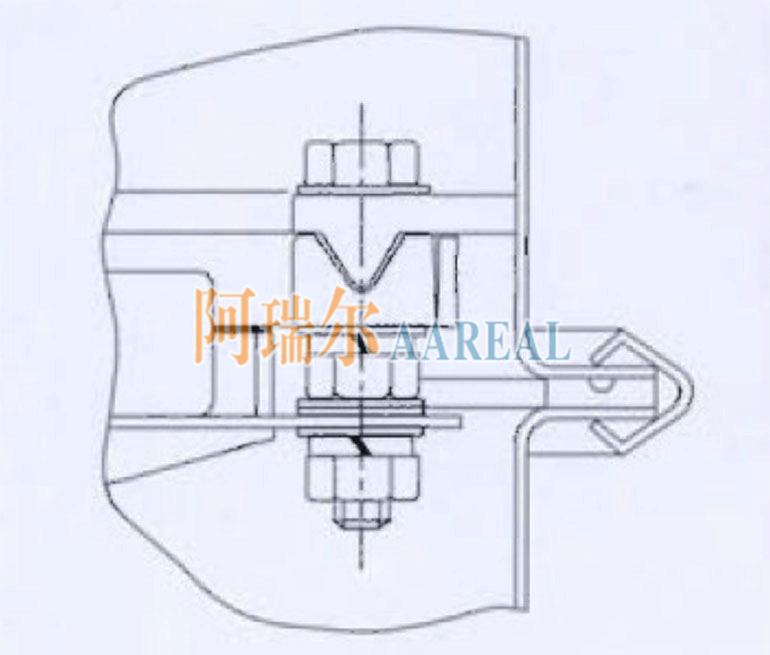

Grid Structure:

Overall Structure:

Standard Specifications:

| Diameter (mm) | 500 | 800 | 1000 | 1200 | 1500 |

| Motor (KW) | 0.75 | 1.5 | 2.2 | 3.7 | 3.7 |

| Vibration Number | 1800 (V.P.M) | 1500 (V.P.M) | 1200 (V.P.M) | ||

| Material | Part contact powder: SUS304Others: hot dip galvanizing on SS400 | ||||

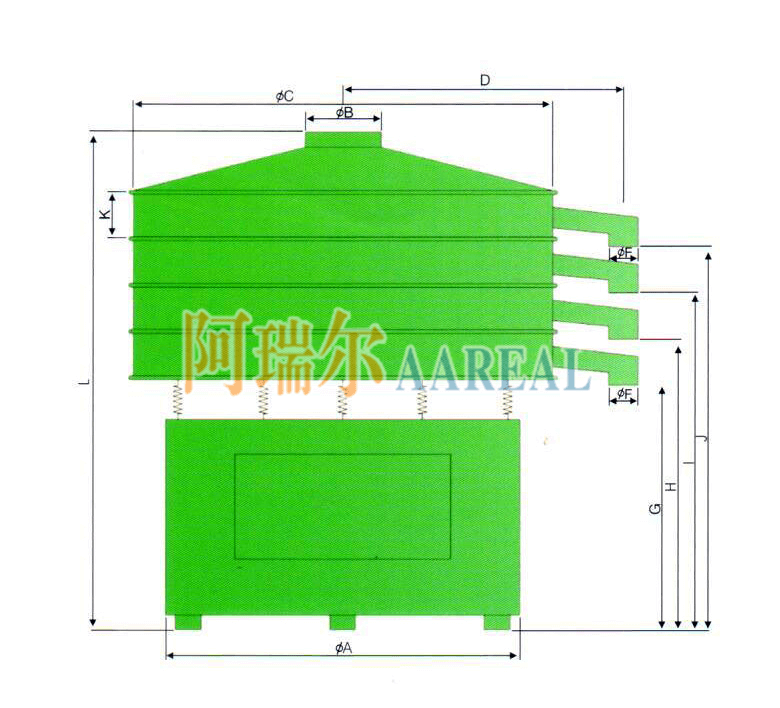

Dimensional Drawing:

Standard Size (mm):

| Model | A | B | C | D | E | F | G | H | I | J | K | L |

| AYGO-500-1AYGO-500-2AYGO-500-3 | 550 | 100 | 490 | 375 | 80 | 80 | 438 | 542 | — | — | 100 | 723 |

| 647 | — | 828 | ||||||||||

| 647 | 752 | 933 | ||||||||||

| AYGO-800-1AYGO-800-2AYGO-800-3 | 815 | 150 | 785 | 575 | 100 | 100 | 495 | 638 | — | — | 127 | 929 |

| 770 | — | 1061 | ||||||||||

| 770 | 902 | 1193 | ||||||||||

| AYGO-1000-1AYGO-1000-2AYGO-1000-3 | 815 | 200 | 917 | 675 | 160 | 100 | 508 | 642 | — | — | 125 | 957 |

| 774 | — | 1089 | ||||||||||

| 774 | 906 | 1221 | ||||||||||

| AYGO-1200-1AYGO-1200-2AYGO-1200-3 | 1030 | 250 | 1112 | 780 | 160 | 160 | 685 | 865 | — | — | 165 | 1200 |

| 1035 | — | 1370 | ||||||||||

| 1035 | 1205 | 1540 | ||||||||||

| AYGO-1500-1AYGO-1500-2AYGO-1500-3 | 1030 | 250 | 1395 | 950 | 200 | 160 | 685 | 880 | — | — | 155 | 1236 |

| 1040 | — | 1396 | ||||||||||

| 1040 | 1200 | 1556 |

Handling Capability Reference:

| Name | Specific Gravity | Particle Size (mesh) | Powerful Type | Ordinary Type | Capability Ratio | |||

| 1 | Chemicals | 0.5 | 400# | AYGO-600-2S | 36Kg/h | AY-600-2S | 10Kg/h | 3.35 |

| 500# | ||||||||

| 2 | Resin | 0.9 | 80# | AYGO-1000-1S | 660Kg/h | AY-1000-1S | 283Kg/h | 2.33 |

| 3 | Silicide Alkali | 1.3 | 60# | AYGO-1000-1S | 970Kg/h | AY-1000-1S | 800Kg/h | 1.21 |

| 4 | Silica | 0.9 | 100# | AYGO-1000-1S | 500Kg/h | AY-1000-1S | 280Kg/h | 1.79 |

| 5 | Processed Silica | 0.5 | 100# | AYGO-1000-1S | 32Kg/h | AY-1000-1S | 28Kg/h | 2.74 |

| 6 | Silica Sand | 1.5 | 35# | AYGO-1000-1S | 2000Kg/h | AY-1000-1S | 1000Kg/h | 2 |

| 7 | Pharmaceuticals | 0.6 | 14# | AYGO-600-2S | 38Kg/h | AY-600-2S | 12Kg/h | 3.35 |

| 50# | ||||||||

| 8 | Abrasive Material | 2.5 | 32# | AYGO-800-1S | 3700Kg/h | AY-800-1S | 560Kg/h | 6.6 |

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

Mobile Phone/WhatsApp/WeChat: 0086-15637361027