Обзор:

Probability vibrating screen is also called mogensen sizer, mogensen vibrating screens, mogensen screen, mogensen sieve, mogensen screener, mogensen screening machine, probability sieve, vibration probability screen, vibrating probability screen, vibration probability sieve, vibrating probability sieve and so on. It is a kind of screening machine that actively use the principle of probability sieving.

The screen surface of mogensen vibrating sizer does linear vibration relying on the vibration excitation device.

This kind of probability mogensen vibrating screen has been widely used in metallurgy, building materials, coal and other industrial departments for medium and fine particle size grading.

Probability vibrating screen adopts multi-layer (usually 3 ~ 6 layer), large dip angle (generally 30°~60°), and large sieve mesh (the screen mesh size is 2~10 times of the separation size) as the screen surface.

The probability screen is a kind of new efficient screening equipment. The moving trajectory of the sieve box is linear. It adopts multi-layer and large inclined angle screen surface. The angle of the screen increases from top to bottom. And using probability theory, the mesh size is larger than the required sieve size, generally 1.2~2.2 times, which greatly improves the screening efficiency and production capacity.

This series of screening machine is a successful example of the combination of probability theory and engineering practice. Its new design concept, unique structure and screening principle have achieved the perfect screening effect of the probability screen and have a wide application prospect.

Compared with ordinary screening machine, this series of mogensen sieve machines have a very high screening efficiency and is widely used in medicine, chemical, food and other industries for fine and medium particles screening.

Работающий ппринцип:

The probability screen adopts the mesh which is bigger than the sieving granularity. It consists of a frame, two vibrating motors and a group of multi-layer overlapping screens whose gradient increase from top to bottom, and the mesh of which decrease progressively.

The whole equipment is mounted on a set of elastic elements. High frequency vibration is obtained by the screen through the rotation of vibration motor.

The mesh size is generally larger than particle size. As soon as the material enters the screen machine, it disintegrates rapidly, thereby eliminating the mesh clogging phenomenon may caused by the critical particles.

Особенностьс:

1. Uniform material distribution and high screening efficiency.

2. The production capacity of unit area is large, and the screen mesh is not easy to jam.

3. Completely enclosed, free of dust, smooth operation, easy to use and maintain.

4. Several kinds of products with different particle sizes can be produced at the same time

5. A single machine can separate 2~7 grain size materials at the same time.

6. The equipment is made of high quality stainless steel, corrosion resistant and long service life.

7. It is easy to replace the screen. The screen tension is moderate. No cross layer and mesh blockage.

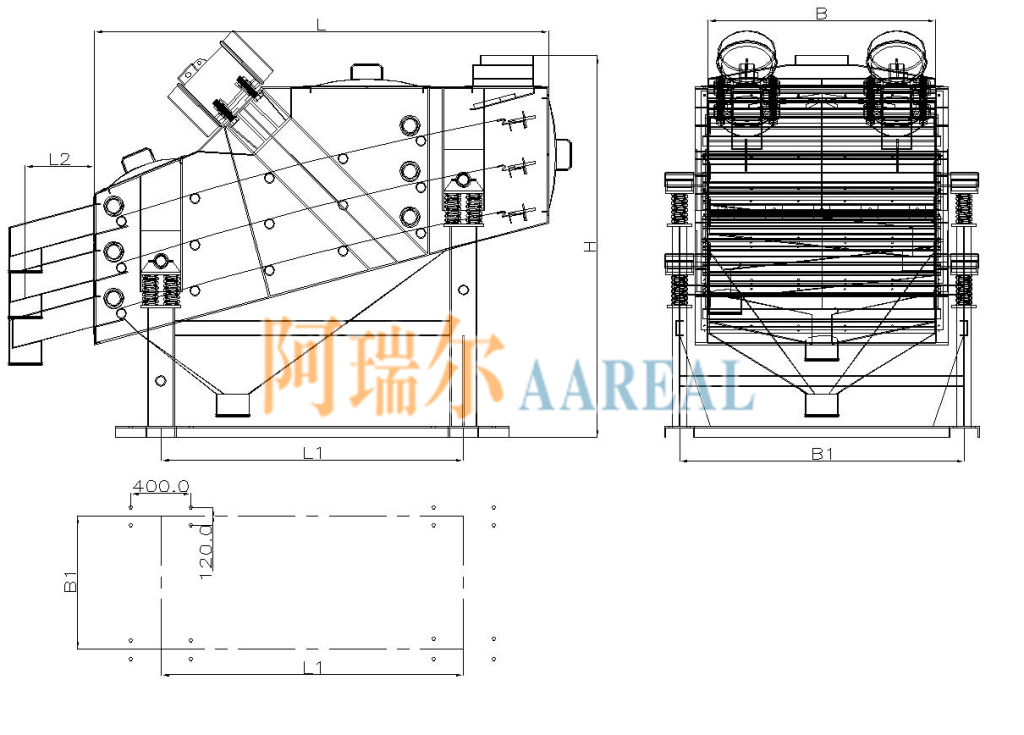

Main Dimensions:

| Модель | л | Л1 | Л2 | Б | Б1 | ЧАС |

| AG-0818 | 1800 | 1100 | 260 | 820 | 1160 | 1800 |

| 2AG-0818 | 1800 | 1100 | 260 | 820 | 1160 | 1900 |

| AG-1020 | 2000 | 1250 | 300 | 1020 | 1380 | 1850 |

| 2AG-1020 | 2000 | 1250 | 300 | 1020 | 1380 | 1980 |

| AG-1024 | 2400 | 1550 | 300 | 1020 | 1380 | 2050 |

| 2AG-1024 | 2400 | 1550 | 300 | 1020 | 1380 | 2150 |

| 3AG-1024 | 2400 | 1550 | 300 | 1020 | 1380 | 2400 |

| AG-1030 | 3000 | 2000 | 300 | 1020 | 1380 | 2200 |

| 2AG-1030 | 3000 | 2000 | 300 | 1020 | 1380 | 2350 |

| AG-1224 | 2400 | 1550 | 380 | 1230 | 1620 | 2050 |

| 2AG-1224 | 2400 | 1550 | 380 | 1230 | 1620 | 2200 |

| 3AG-1224 | 2400 | 1550 | 380 | 1230 | 1620 | 2450 |

| AG-1230 | 3000 | 2000 | 380 | 1230 | 1620 | 2200 |

| 2AG-1230 | 3000 | 2000 | 380 | 1230 | 1620 | 2350 |

| 3AG-1230 | 3000 | 2000 | 380 | 1230 | 1620 | 2600 |

| AG-1236 | 3600 | 2350 | 380 | 1230 | 1620 | 2350 |

| 2AG-1236 | 3600 | 2350 | 380 | 1230 | 1620 | 2500 |

| AG-1530 | 3000 | 2000 | 450 | 1530 | 1930 | 2200 |

| 2AG-1530 | 3000 | 2000 | 450 | 1530 | 1930 | 2350 |

| 3AG-1530 | 3000 | 2000 | 450 | 1530 | 1930 | 2600 |

| AG-1536 | 3600 | 2350 | 450 | 1530 | 1930 | 2350 |

| 2AG-1536 | 3600 | 2350 | 450 | 1530 | 1930 | 2600 |

| AG-1836 | 3600 | 2350 | 500 | 1830 | 2300 | 2400 |

| 2AG-1836 | 3600 | 2350 | 500 | 1830 | 2300 | 2550 |

| 3AG-1836 | 3600 | 2350 | 500 | 1830 | 2300 | 2810 |

| AG-1842 | 4200 | 2800 | 500 | 1830 | 2300 | 2560 |

| 2AG-1842 | 4200 | 2800 | 500 | 1830 | 2300 | 2720 |

Контактное лицо: г-жа Мэги

Электронная почта: sale@aarealmachine.com

magiecn@gmail.com

Мобильный телефон/WhatsApp/WeChat: 0086-15637361027