This is a 2-deck linear vibrating screen, screen width 500mm, screen length 4000mm, made of carbon steel (Q235). It can be used to convey material while screening.

What is Linear Vibrating Screen? Linear vibrating screen is also know as прямоугольный сепаратор, rectangular vibrating separator, linear vibrating sieve etc. It uses 2 vibration motors as the driving source. When two vibration motors rotate synchronously and in opposite directions, the exciting forces generated by their eccentric blocks cancel each other out in the direction parallel to the motor axis and add up to a resultant force in the direction perpendicular to the motor axis, so the motion trajectory of the screen is a straight line. The two motor shafts have an inclination angle in the vertical direction relative to the screen surface. Under the combined force of the exciting force and the self-weight of the material, the material is thrown up and jumped or moves forward in a straight line on the screen surface, thereby achieving the purpose of screening and grading the material. It is suitable for screening various dry powdery or granular materials with a particle size of 0.074-5mm, a water content of less than 7%, and no viscosity. The feed particle size is not more than 10mm.

The linear vibrating sieve is mainly composed of screen box, screen frame, screen, vibration motor, motor base, vibration damping spring, bracket etc.

- Screen box: It is welded by several steel plates of different thicknesses, has certain strength and rigidity, and is the main component of the screen machine.

- Screen frame: It is made of pine or wood with small deformation, mainly used to keep the screen flat and achieve normal screening.

- Screen: There are several screens such as low carbon steel, brass, bronze, stainless steel wire, etc.

- Vibration motor (For details on the use and maintenance methods, please refer to the vibration motor instruction manual).

- Motor base: Install the vibration motor, and the connecting screws must be tightened before use, especially in the first three days of the trial of the new screen machine, and must be tightened repeatedly to avoid loosening and causing accidents.

- Vibration damping spring: It prevents vibration from being transmitted to the ground, and supports the entire weight of the screen box. When installing, the spring must be perpendicular to the ground.

- Bracket: It consists of four pillars and two channel steels, supporting the screen box. When installing, the pillars must be perpendicular to the ground, and the channel steels under the two pillars should be parallel to each other.

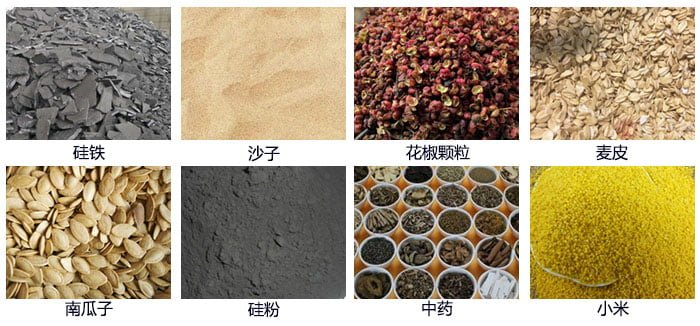

The rectangular vibrating screen is commonly used to screen ferrosilicon, sand, pepper particles, wheat bran, pumpkin seeds, silicon powder, sugar, Chinese medicine, betel nut, silicon carbide powder, stone, activated carbon particles, soil, gravel, millet, slurry, shell, cooked sesame, machine-made sand, chrysanthemum, quartz sand, construction waste, coke powder, plastic particles, river sand and other materials.

Main Technical Parameters of Linear Vibrating Sieve:

| Модель | Размер экрана (мм) | Слои экрана | Размер ячейки | Емкость (т/ч) | Частота | Double Amplitude (мм) | Власть (кВт) | Angle | Dimension (L*W*H) (mm) |

| AZ-515 | 500×1500 | 1-5 | 2-200 | 0.12-20 | 960 | 6-8 | 2×0.37 | 45-60 | 2140×808×848 |

| AZ-520 | 500×2000 | 2-200 | 0.12-20 | 960 | 6-8 | 2×0.37 | 45-60 | 2140×808×848 | |

| AZ-525 | 500×2500 | 2-200 | 0.12-20 | 960 | 6-8 | 2×0.55 | 45-60 | 2750×808×938 | |

| AZ-1020 | 100×2000 | 2-200 | 0.11-20 | 960 | 6-8 | 2×0.55 | 45-60 | 2219×1320×960 | |

| AZ-1025 | 1000×2500 | 2-200 | 0.18-15 | 960 | 6-8 | 2×0.75 | 45-60 | 2269×1320×960 | |

| AZ-1030 | 1000×2500 | 2-200 | 0.1-20 | 960 | 6-8 | 2×1.1 | 45-60 | 3219×1340×1120 |

Our company can make various screening equipments according to different screening requirment, such as Rotex type gyratory screen for detergent, Apex type side access door gyratory screener for frac sand, Sweco type gyratory sifter for silica sand, tumbler screening machine for aluminium oxide powder, high frequency screen for calcium carbonate etc. Welcome to send us RFQs if you have such requirement.

Контактное лицо: г-жа Мэги

Электронная почта: sale@aarealmachine.com

magiecn@gmail.com

Мобильный телефон/WhatsApp: 0086-15637361027.