Overview:

Trommel screen is also called rotary screen, rotary trommel screen, trommel vibrating screen, trommel vibrating sieve, drum screen, drum sieve, drum screening machine, revolving screen, cylinder round sifter, cylinder rotary screen, revolving cylindrical sieve, cylinder revolving screen, roller screen, roller sieve etc.

The rotary screen is the special screening machine for power plant, coking plant, building materials, metallurgy, chemical industry, mining, ceramics and other industries. It has overcome the screen plugging problem caused by circular vibrating screen and linear screen in the process of screening wet materials, which has improved the output and reliability of the screening system, and has been widely praised by the users.

Working Principle:

The rotary trommel screen is made up of motor, reducer, drum device, rack, seal cover, inlet and outlet. The machine is inclined to be mounted on the rack. The motor is connected with the drum device through the coupling via reducer, driving the drum device to rotate around its axis.

When materials enter into the drum device, as the result of the inclination and rotation of the drum device, the materials on the screen surface flip and roll, making the qualified material (undersize product) discharge from the outlet at the bottom of the drum, and unqualified material (oversize product) discharge through the outlet at the end of the drum. Due to the material flipping and rolling inside the drum, the material that is stuck in the middle of the sieve can be ejected, so as to prevent the screen mesh from being blocked.

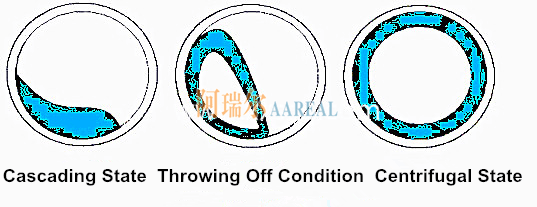

Material Running State in the Rotary Screen

Features:

1. Small power and low energy consumption. There is self-cleaning device in the drum. The mesh is not easily blocked.

2. Small occupation space, low investment cost, stable and reliable operation, high screening efficiency and large output.

3. Simple process layout, convenient installation and maintenance, easy operation.

4. Have strong adaptability to materials. Material that is sticky, with high humidity, dirty and miscellaneous can be screened.

5. The feeding mode is diverse: manual and mechanical transmission. It can produce in large quantities.

6. The center screen adopts annular flat steel ring design. With good wear resistance, long service life, simple structure and convenient maintenance.

Application:

The rotary trommel screen is mainly used for grading according to the material particle size. It is widely used in electric power, mining, metallurgy, building materials, chemical and other production industries. And it is commonly used for grading of refractory materials, coal, chemical fertilizer, sand field stone, and for screening of coal, coke, lime, gravel mine and other clammy materials, making the product structure more even and orderly, so as to meet the needs of production.

1. Widely used in various types of materials screening, whether it is fault coal, coal slime, soft coal or other materials, can be smoothly screened. It is a popular equipment for refractory materials, coal, river sand grading and sandstone blocks grading.

2. Widely used in chemical industry, food, mining, fodder, paper making, sugar manufacturing and other fine powder raw material of powerful screening and classification operation. And it is especially suitable for heavy soda ash, light soda ash, quartz sand, plastic powder, carbon black, activated carbon, resin powder, all kinds of sugar powder, metallurgy powder etc.

3. Used for gravel grading in the quarry and separate mud and limestone powder.

4. Used for sand and stone separation in the aggregate plant

5. Used to separate lump coal and pulverized coal separation and coal washing (Part of the coal washing machine)

6. Used in block classification and powder material separation in the chemical industry and mineral processing industry.

Grading:

According to different classification requirments, trommel screen hierarchical level is general 1~4 section from fine to coarse material.

Material from fine to coarse is to be screened respectively from the first section to the last section.

And the material greater than the last section screen mesh is to be discharged from outlet.

Technical Parameters:

1. driving device 2. coarse material discharge opening 3. seal cover 4. drum body

5. undersize material discharge opening 6. retaining plate 7. feed inlet 8. bracket

| Model | Capacity(t/h) | Screen Drum Diameter (mm) | Length(m) | Motor Power (KW) |

| GTS600 | 5-10 | ¢600 | 1000 | 1.5 |

| GTS800 | 8-15 | ¢800 | 1200 | 2.2 |

| GTS1000 | 15-30 | ¢1000 | 1500 | 3 |

| GTS1200 | 20-50 | ¢1200 | 1800 | 5.5 |

| GTS1500 | 40-80 | ¢1500 | 2000 | 7.5 |

| GTS1800 | 80-150 | ¢1800 | 2000 | 11 |

| GTS2000 | 130-200 | ¢2000 | 2500 | 11 |

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

Mobile Phone/WhatsApp/WeChat: 0086-15637361027