Introduction:

The vacuum feeder uses an electric air pump as the automatic feeding system of the vacuum source. It has the characteristics of high negative pressure and large air volume, which is suitable for long-distance and large-capacity transportation of heavy materials. With high-precision titanium filter rods, the filtration accuracy can reach 0.3μm, widely used in various light and heavy industries such as chemical, pharmaceutical, food, metallurgy, building materials, agricultural and sideline industries etc.

The vacuum feeder adopts closed pipeline conveying, preventing dust environmental pollution, improving the working environment, while reducing environmental and personnel pollution to materials, and improving cleanliness. It takes up small space and can complete powder transportation in a small space. This feeder can reduce labor intensity and improve working efficiency. It is the first choice for conveying most powder materials.

Features:

1. The whole machine is powered by a vortex air pump, which is oil-free, water-free and maintenance-free.

2. The whole conveying process is completed in a completely closed state, eliminating dust pollution.

3. The machine is a building block mechanism, and the barrel is connected with a quick-opening clamp, which is convenient and quick to disassemble and clean.

4. Low energy consumption, low noise and convenient control.

Working Principle:

The electromagnetic valve controls the compressed air into the suction feeding tube directly. The compressed air accelerates the flow to produce negative pressure, and the material is sent to the feed cylinder. The air is discharged from the filter to achieve continuous conveying of materials.

The vacuum feeder is composed of vacuum pump (no oil, no water), membrane filter bag filter, compressed air blowback device, pneumatic discharge door device, vacuum hopper, stainless steel adjustable suction gun, delivery hose and other components.

Technical Parameters:

| Model | Power (Kw) | Capacity (t/h) | Air Supply Pressure (MPa) | Suction Tube Diameter (mm) |

| AKS-20-2 | 1.5 | 0.1-0.5 | 0.6 | 38 |

| AKS-20-4 | 2.2 | 0.3-1.5 | 0.6 | 38 |

| AKS-30-2 | 3.0 | 0.5-2 | 0.6 | 51 |

| AKS-30-4 | 5.5 | 0.8-3 | 0.6 | 51 |

| AKS-30-6 | 7.5 | 1.5-5 | 0.6 | 51 |

| AKS-45-4 | 7.5 | 2-6 | 0.6 | 63 |

| AKS-45-6 | 7.5 | 3-9 | 0.6 | 76 |

| AKS-63-4 | 11 | 6-16 | 0.6 | 76 |

| AKS-63-6 | 11 | 8-25 | 0.6 | 102 |

Application:

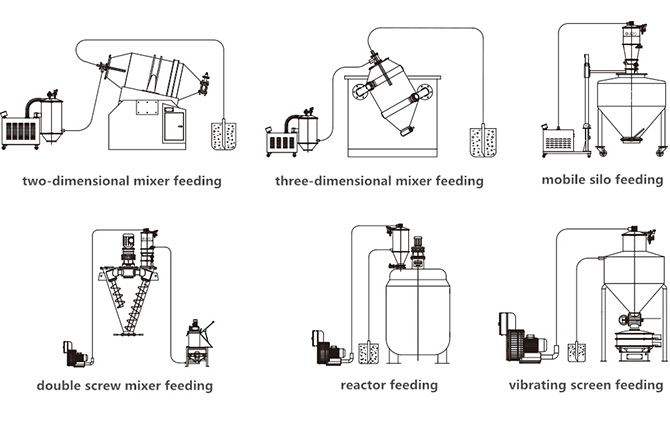

The vacuum feeder can automatically transport various materials to the hoppers of silos, screening machines, reactor, mixer, packaging machines, injection molding machines, crushers and other equipments, which reduces the labor intensity of workers and solves the problem of dust overflow during feeding.