Introduction:

Compared to the traditional AD model gyratory screen, the side door gyratory screen has a lower maintenance cost and faster screen replacement time. The light weight and pre-tensioned screen panels allow for easy inspection and screen replacement in a few minutes.

Side door gyratory screen is used for high precision and large-capacity screening for 40 μm~10mm granules. It can be used in the screening of thousands of materials such as salt, sugar, soda ash, silica sand, ceramsite sand, urea, glass beads, alumina, clay, limestone, flour, milk powder, coffee, cereal, spices, cocoa powder, glucose, starch, ammonium nitrate, phosphate, potassium hydroxide, wood chip, flaking, wood powder, medicines, plastic granule, metal powder and so on.

Features:

(1) Change the structure of the traditional gyratory screen to replace the screen from the top, the side door type realizes the replacement of the screen from both sides of the screen box.

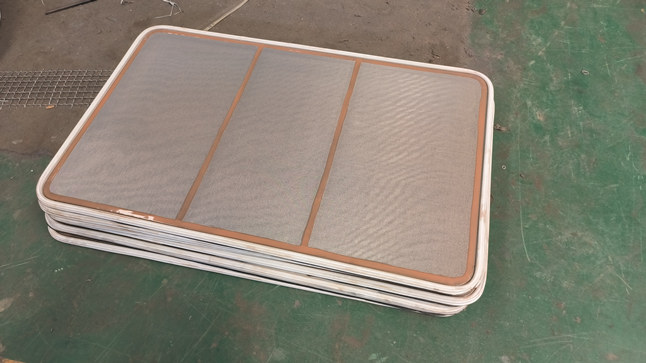

(2) Change the structure of the whole layer of the traditional sieve machine. Each layer of the side door type is composed of multiple independent small sieve plates. Each small sieve plate is 1/2~1/8 of the weight and area of the original sieve plate.

(3) Change the operation process of traditional gyratory screen that when replace the lower screen, the user must remove the upper screen and screen cover. The side door type can directly replace the lower screen without moving the upper screen plate or screen cover, saving unnecessary work.

(4) For traditional gyratory screen, if the screen is broken somewhere, the whole screen needs to be replaced, but for the side door type, people only need to replace a small piece of the damaged screen plate in each layer, which also saves unnecessary operations.

(5) The traditional screen replacement operation is too cumbersome, the time is too long, so that the entire production line downtime is too long, affecting the output. The side door type makes the screen replacement simple, and the time is shortened in 10 minutes.

(6) The screen replacement work is safe. Since each layer of the screen is divided into 2 to 8 separate small screen plates, each small screen plate weight will be within 20 kg, which is quite safe for the operator.

(7) Since the weight and area of the small screen plate of each layer are 1/2 to 1/8 of the original screen plate, there is no need to use auxiliary equipment such as lifting when replacing the screen, and the screen replacement is faster.

(8) Since the use of small sieve plates, no more space is required when replacing the screen, saving equipment installation space.

(9) Based on the characteristics of side door type mentioned above, such as the screen plate area is controllable, the weight is small, the door can be opened on the side, there is no interference between the screen plate layers, and the small block screen plates are also independent of each other, which can make the fine screen meet some application environments that have harsh requirements for screen replacement time and space, such as strong bonding materials, abrasive materials and application environments that require frequent replacement of different aperture screens.

Working Principle:

The gyratory reciprocating motion of gyratory screen begins with a circular motion at the feed end, gradually diminishing along the length of the machine to elliptical movement in the middle, and finally to an almost straight-line motion at the discharge end.

1.At the feed end: Circular Motion

The gyratory movement at the feed end can quickly complete the material’s spreading, stratifying, separating and moving forward across the full width of the screen surface.

2.At center: Elliptical Motion

The long-stroke elliptical movement can enhance material stratification, which help to improve the screening capacity.

3.At the discharge end: Reciprocating Motion

The reciprocating motion at the discharge end can remove the near-size particles, improving the screening efficiency. And it has almost no particles jump vertically, which ensures that the material is in constant contact with the screen surface.

Technical Parameters:

| Model | Screen Area (m²) | Layers of Screen | Power (KW) | Ref. Dimensions (mm) |

| ADC-515 | 0.75 | 1~2 | 1.5 | 3300*810*1800 |

| ADC-1021 | 2.1 | 1~2 | 3 | 3900*1310*1800 |

| ADC-1030 | 3 | 1~3 | 4 | 5400*2120*2100 |

| ADC-1036 | 3.6 | 1~3 | 4 | 6000*2120*2100 |

| ADC-1530 | 4.5 | 1~3 | 5.5 | 5400*2620*2590 |

| ADC-1536 | 5.4 | 1~3 | 5.5 | 6000*2620*2590 |

| ADC-1836 | 6.48 | 1~3 | 7.5 | 6000*2920*2590 |

| ADC-1840 | 7.2 | 1~3 | 7.5 | 6400*2920*2590 |

| ADC-1550 | 7.5 | 1~3 | 7.5 | 7250*2620*2590 |

Motor

Exciter

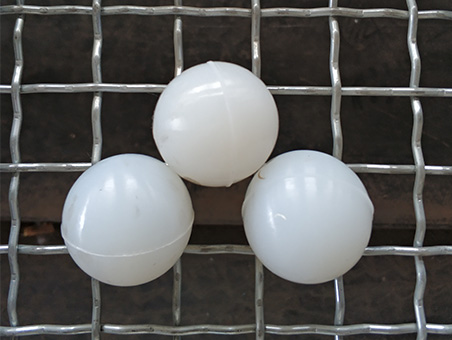

Mesh Cleaning Balls

Ball Deck

Screen Panel

Screen Panel Tightening Device

Drag Link

Suspension Cable

1. Seat Installation:

As the driving system of this machine has a balance function, outward transmitting force is smaller, it can be installed directly on the ground, or steel structure frame or platform that allow vibration.

2. Cable Suspension Installation:

The sieving machine can be hoisted by cables from the four corners of the machine to insulate the balance force of the sieving machine from the surrounding structure.

Application:

Abrasive: glass beads, slag, alumina, sand and other abrasive materials

Animal feed: feed powder and chips, meat paste and small food

Carbon products: coking coal, graphite, charcoal etc.

Chemical products: hundreds of different compounds

Clay: product classification

Fertilizer: raw material sieving and finished product fine screening. Including ammonium nitrate, phosphate, potassium hydroxide, urea and other compounds

Food: sugar, flour, milk powder, coffee, cereals, rice, nuts, condiments, cocoa powder, glucose, starch etc. Grain cleaning: corn, wheat, soybean and other cereals peeling and cleaning Ore: ore, rubble, limestone, soda ash and salt

Paper: paper pulp, coating

Fiberboard: wood chips, flaking, bits of wood, to make high quality fiberboard

Drug: many large drug manufacturers use AAREAL screening machines, which meet the health standard design, to achieve precise and effective separation and cleaning

Plastic: plastic particles, plastic powder

Powder metal: aluminum, copper, iron, nickel, steel, zinc and many other metal powders Recycling of resources:used in the recycling of various materials, such as PET recycling etc.

Steelmaking: classification of steel shot and metal filing