Introduction:

The high-frequency fine screen is also well known as high frequency screen, high frequency vibrating screen, vibrating wire screen, vibrating mesh screen, vibrating wire cloth screen machine etc.. The screen surface vibrates, and screen box does not move. It is used to sift 0.07~10 mm material.

Features:

1. High screening efficiency and large processing capacity. According to different screens, the production capacity can be as high as 20 t/h*m².

2. The screen is free from clogging, with excellent screening results, and the screening accuracy is as high as 85~95%.

3. Gentle screening. Only the screen vibrates, and the screen box does not vibrate. The dynamic load is extremely low, and the equipment is easy to install.

4. The replacement of the screen is very simple.

5. Low driving power.

6. Environmental protection: dustproof and low noise.

Working Principle:

The high frequency fine screen adopts electromagnetic vibrator or unbalanced motor as the power source, the high-frequency vibration directly excites the screen through the vibrating shaft, and the acceleration perpendicular to the screen exceeds 15g, making the screen work in a near resonance state. The screen surface amplitude is 1~3mm, and the vibration strength is 2-4 times that of the general vibrating screen machine. Under the action of the high frequency vibration of the screen surface, the materials flow, stratify and pass through the screen surface, which overcomes the adhesion force between the materials, makes the material bed loose, let the particles stuck in the mesh and near-hole particles pop out, keeps the screen clean, and the screen is not easy to block holes. Even difficult-to-screen materials can be screened with high efficiency at a moving speed of 0.8~1 m/s.

Technical Parameters:

The screening angle is adjustable

Driving source: electromagnetic vibrator or unbalanced motor, working frequency is 50 HZ/60HZ

Up to 4 layers of screens can complete the production of 2~5 products

Width of screen: 0.95~1.75 m

Length of screen: 1.45~5.40 m

Screen angle: 30~45°

| Model | Driving Source | Ref. Photo | Remarks |

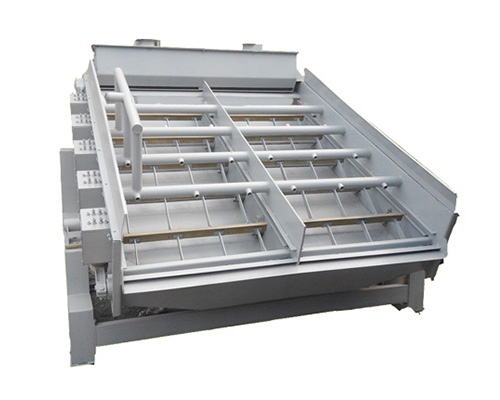

| WA | electromagnetic vibrators |  |  |

| WAU | unbalanced motors |  |  |

| WAW | vibration motors |  | It can complete one or two layers screening |

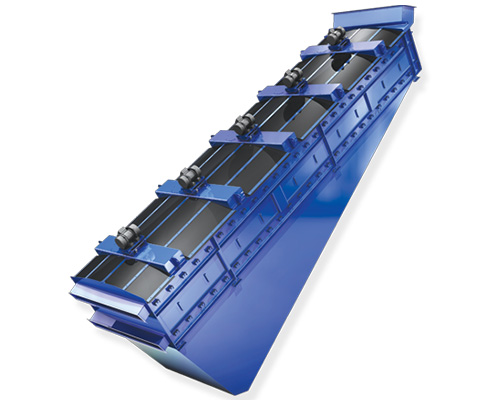

| WAF | unbalanced motors (or electromagnetic vibrators) + two vibration motors |  | It makes the material present linear vibration, which can effectively reduce the height of the screening machine |

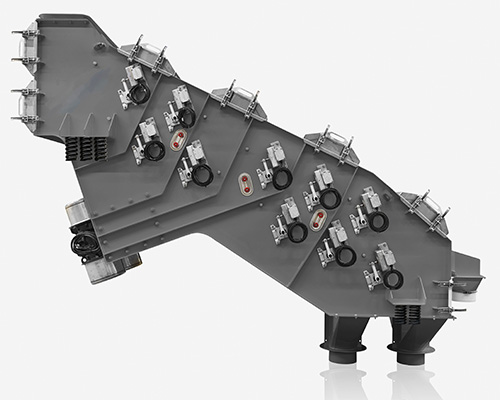

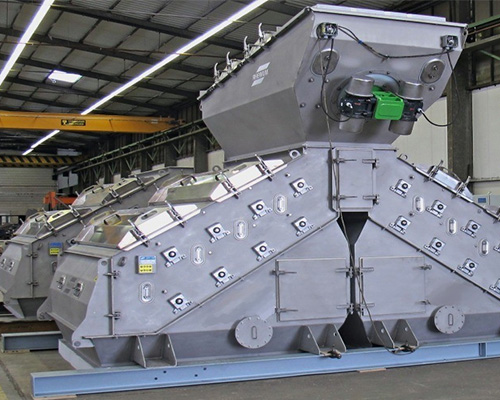

| WAD | unbalanced motors (or electromagnetic vibrators) |  | The automatic distributor can realize the simultaneous operation of two screens, which greatly improves the work efficiency |

Application:

This kind of vibrating screen is suitable for dry and wet screening, classification, dehydration and coarse separation of fine particle materials. It is widely used in the fertilizer and compound fertilizer industry, ore dressing (iron ore, quartz sand, kaolin etc.), dewatering (coal slime dewatering, dry tailings dehydration, gold ore powder carbon recovery dehydration etc.), screening of dry material etc.