Introduction:

Electromagnetic vibrating feeder is widely used in mining, metallurgy, coal, building materials, light industry, electric power, machinery, grain and other kinds of industries. It is used for massive, granular and powdered materials from the storage silo or hopper homogeneous and continuous feeding or quantificationally feeding into the receiving device. For example, belt conveyor, bucket elevator, screening equipment, crusher, grinder and other equipments’ quantitative feeding, automatic batching and quantitative packaging etc.

Features:

(1) Energy saving and high efficiency, simple to use, less investment, small volume, light weight, convenient maintenance.

(2) No rotating parts. No need bearings, reducingmechanism and lubricating oil etc.

(3) Less power consumption, small startup current, low noise.

(4) The feed trough wear is small. Suitable for conveying material with big wear and tear

(5) The equipment can realize automation if equiped with electronic scale or microcomputer control.

(6) After vibrationexciter starts, the amplitude can instantaneously achieve stable value.

(7) Vibrator start in instantaneous amplitude can achieve stable value, immediately after the same instantaneous amplitude disappears when parking, which can enhance the accuracy of automatic control, at the same time feeder can start directly in full load condition. Similarly, amplitude instantaneously disappears when stopping. In this way can enhance the accuracy of automatic control, and at the same time, the feeder can be directly started at full loading case.

Working Principle:

The current of electromagnetic coil of electromagnetic vibration feeder passes through single phase half-wave rectification. When the coil is connected, the current passes through in the positive half week, and a pulse electromagnetic force between armature and iron core attracts each other. Then the groove moves backwards, the main spring deforms and stores a certain potential energy. There is no current passing through the coil in the negative half-cycle, and the electromagnetic force disappears, and the main spring releases energy. The armature and iron core move forward from the groove in the opposite direction, so the electromagnetic vibration feeder vibrates 3000 times per minute at the frequency of AC power supply. Because the bottom plane of the groove has a certain angle with the action line of exciting force, the material in the groove moves forward continuously along the parabolic trajectory. The feeding quantity of electromagnetic vibration feeder can be controlled by adjusting the rectifying voltage. The feeder is supplied by SCR rectifier. The output voltage can be controlled by changing the conduction angle of thyristor. According to the operating conditions, different signals can be used to control the conduction angle of thyristor to achieve the purpose of automatic quantitative feeding.

Running Fault and Treatment Method:

| NO. | Fault Character | Fault Cause | Treatment Method |

| 1 | after turning on power supply, the machine does not vibrate | 1. the fuse blew out | replace fuse |

| 2. coil wire short circuit or lead wire is broken | use megger or ohmmeter to check resistance, handle short circuit or connect lead wire | ||

| 2 | weak vibration, adjust potentiometer shows small amplitude reflection, do not work or current is on the high side | 1. SCR breakdown | replace SCR (Silicon Controlled Rectifier) |

| 2. Air gap blockage, and gap between the plate spring blockage | clear blockage | ||

| 3 | machine noise is big. adjust potentiometer, amplitude reflects irregular, accompanied by a violent crash | 1. plate spring break | replace the new spring |

| 2.vibrator and trough body joint bolt breaks or looses | replace or screw down the bolt | ||

| 3.iron core and the armature collided | adjust the air gap to the standard 2 mm | ||

| 4 | machine works intermittently or current fluctuates | wire coil damage | check whether the coil layer or interturn is short circuit, and whether the lead wire connector is virtual connection, then repair or replace the coil |

| 5 | no-load test is normal. | improper design of the stock bin discharging hole makes the feed trough bear the big stock column pressure | redesign or improve the feed inlet to reduce stock column pressure |

| after load, amplitude decrease more | |||

| 6 | only the current is on the high side, | maybe the air gap is too big | adjust the air gap to the standard 2 mm |

| the rest is normal |

Technical Parameters:

| Type | Model | Capacity(t/h) | Feed Size (mm) | Double Vibration Amplitude (mm) | Voltage (V) | Electric Current (A) | Power (Kw) | Matched Control Box | ||

| Horizontal | -10° | Working Current | Indication Current | |||||||

| Basic Type | GZ1 | 5 | 7 | 50 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ-5G2 |

| GZ2 | 10 | 14 | 50 | 3.0 | 2.3 | 0.15 | ||||

| GZ3 | 25 | 35 | 75 | 4.58 | 3.8 | 0.2 | ||||

| GZ4 | 50 | 70 | 100 | 8.4 | 7 | 0.45 | XKZ-20G2 | |||

| GZ5 | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | ||||

| GZ6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.2 | XKZ-20G3 | |

| GZ7 | 250 | 350 | 250 | 24.6 | 20 | 3 | ||||

| GZ8 | 400 | 560 | 300 | 39.4 | 32 | 4 | ||||

| GZ9 | 600 | 840 | 350 | 47.6 | 38.6 | 5.5 | XKZ-200G3 | |||

| GZ10 | 750 | 1050 | 500 | 39.4*2 | 32*2 | 4*2 | XKZS-200G3 | |||

| GZ11 | 1000 | 1400 | 500 | 47.6*2 | 38.6*2 | 5.5*2 | ||||

| Up Vibration Type | GZ3S | 25 | 35 | 75 | 1.75 | 220 | 4.58 | 3.8 | 0.2 | XKZ-5G2 |

| GZ4S | 50 | 70 | 100 | 8.4 | 7 | 0.45 | XKZ-20G2 | |||

| GZ5S | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | ||||

| GZ6S | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | |

| GZ7S | 250 | 350 | 250 | 24.6 | 0 | 3 | XKZ-100G3 | |||

| GZ8S | 400 | 560 | 300 | 39.4 | 32 | 4 | ||||

| Closed Type | GZ1F | 4 | 5.6 | 40 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ-5G2 |

| GZ2F | 8 | 11.2 | 40 | 3 | 2.3 | 0.15 | ||||

| GZ3F | 20 | 28 | 60 | 4.58 | 3.8 | 0.2 | ||||

| GZ4F | 40 | 56 | 60 | 8.4 | 7 | 0.45 | XKZ-20G2 | |||

| GZ5F | 80 | 112 | 80 | 12.7 | 10.6 | 0.65 | ||||

| GZ6F | 120 | 168 | 80 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | |

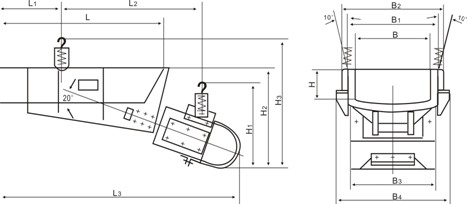

Basic Type (Open Type):

| Model | B | B1 | B2 | B3 | B4 | L | L1 | L2 | L3 | H | H1 | H2 | H3 |

| GZ1 | 200 | 280 | 340 | 296 | 376 | 600 | 209 | 550 | 910 | 100 | 350 | 360 | 485 |

| GZ2 | 300 | 388 | 456 | 400 | 506 | 800 | 310 | 660 | 1171 | 120 | 430 | 450 | 600 |

| GZ3 | 400 | 496 | 518 | 452 | 574 | 900 | 311 | 790 | 1325 | 150 | 480 | 520 | 675 |

| GZ4 | 500 | 620 | 682 | 581 | 762 | 1100 | 413 | 965 | 1615 | 200 | 550 | 645 | 814 |

| GZ5 | 700 | 761 | 850 | 650 | 840 | 1200 | 465 | 1050 | 1815 | 250 | 647 | 765 | 980 |

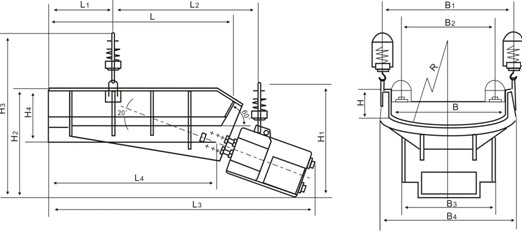

Basic Type (Closed Type):

| Model | B | B1 | B2 | B3 | B4 | L | L1 | L2 | L3 | L4 | H | H1 | H2 | H3 | H4 | R |

| GZ6 | 900 | 1057 | 720 | 860 | 1092 | 1600 | 500 | 1360 | 2410 | 1409 | 250 | 1090 | 1030 | 1530 | 460 | 1800 |

| GZ7 | 1100 | 1257 | 840 | 1030 | 1332 | 1800 | 650 | 1465 | 2800 | 1585 | 250 | 1300 | 1130 | 1740 | 500 | 2200 |

| GZ8 | 1300 | 1476 | 1000 | 1166 | 1556 | 2200 | 750 | 1800 | 3302 | 1938 | 300 | 1460 | 1340 | 1695 | 607 | 2600 |

| GZ9 | 1500 | 1676 | 1010 | 1228 | 1776 | 2400 | 800 | 2000 | 3515 | 2100 | 300 | 1520 | 1440 | 2200 | 660 | 3500 |

Application:

Electromagnetic vibrating feeder is widely used in mining, metallurgy, coal, building materials, light industry, electric power, machinery, grain and other kinds of industries. It is used for massive, granular and powdered materials from the storage silo or hopper homogeneous and continuous feeding or quantificationally feeding into the receiving device. For example, belt conveyor, bucket elevator, screening equipment, crusher, grinder and other equipments’ quantitative feeding, automatic batching and quantitative packaging etc.