Overview:

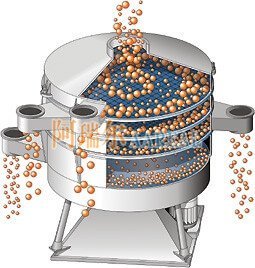

Tumbler screener is also called tumbler screening machine, tumbler sieve, swinging screen, swinging sieve, rocking sieve, shaking sieve machine etc.

The simplest sieving is using your hands with the staring of your eyes. Tumbler screening machine is the mechanical simulation for this. Swinging sieve is the most effective screening machine that simulates the principle of artificial screening. The screening accuracy, efficiency and screen service life are 5~10 times of regular round vibrating sieve machine. It conforms to all fine and ultra-fine powder and granular materials, especially suitable for materials which are difficult to classify.

Tumbler sieve is often used to screen xylitol, food additives, citric acid, EPS, PAA, PVC, glass beads etc.

Working Principle:

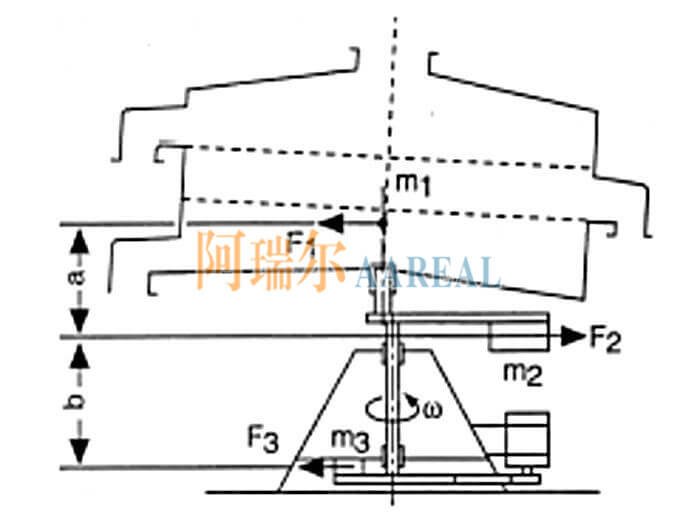

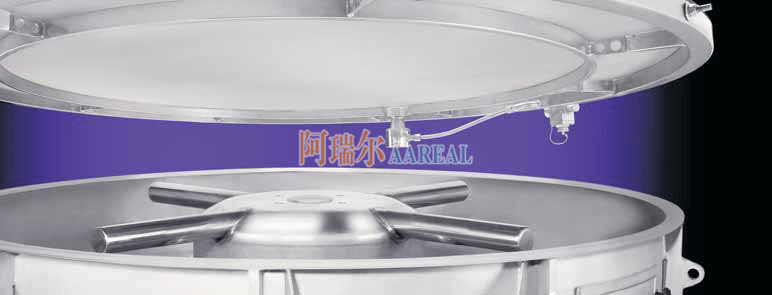

The tumbler screener utilizes the humanoid screening principle. To imitate the movement of artificial screening action and do three-dimensional circular motion, skillfully combine the sieving (planar circular motion) and winnowing (upward parabolic motion), establish horizontal and throwing three-dimensional tumbling movement, make the material in the screen surface appear involute spiral movement. The material takes a relatively long distance across the relative area, and the landing screen time of the material is more than 85%, improving the screen through rate. The screening accuracy is as high as 90%~99%, increasing the yield.

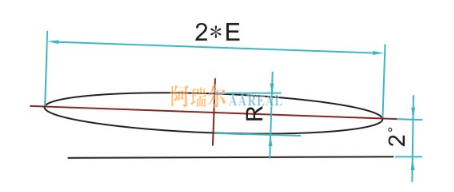

According to the physical properties of the material and the different screening requirements of customers, we can adjust the independent and adjustable rotate speed, eccentricity, radial force, tangential force, so as to change the material stay time on the screen surface and the moving route to achieve the best screening effect.

Screen Parameter Control Diagram:

Only recording the best running setup parameters, you can reproduce the best operation at any time to ensure the quality of your products.

Date: Material: PVC Powder

Min-1 220

Radial Direction R 8

Tangent Direction T 2

Eccentricity E 35

BALANCE IS IMPORTANT !!

With Pneumatic Lifting Device

Application:

Chemical, food and spices, plastics and Synthetic Resin, mining, medicine, wood and plywood, metallurgy, feed, rubber, fodder, fertilizer, sugar, salt, renewable industry and so on.

Features:

1. Soft rock screening will not destroy the particles original structure of the material and not easy to produce static electricity. It is the best choice for material that is flammable, explosive and easy to generate static. And effectively extend the life of equipment parts.

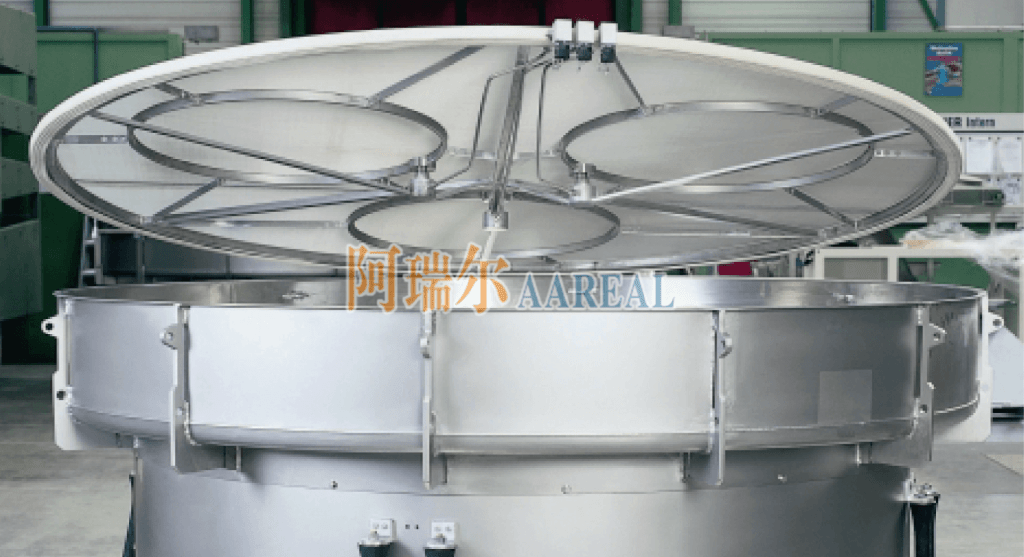

2. with circular building block type assembling structure, easy assembly and disassembly. The discharge port is free to rotate 360 degrees.

3. Can be used up to 7 layers, can produce up to 8 particle sizes.

4. The screen structure is diverse. It can be not only spliced, but also integrally bonded.

5. The vertical direction acceleration value of the material particles is low, so that the screen mesh is not easy to damage, prolonging the service life of the screen.

6. large-scale screening machine can be installed pneumatic lifting device to reduce the difficulty of screen replacement.

7. he noise is low to 75dB. Fully enclosed and more environmentally friendly.

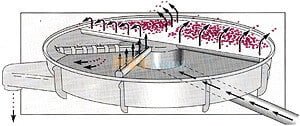

Mesh Cleaning Method:

1. Bounce Ball + PU Ring Cleaning

2. Brush Cleaning Device

3. Compressed Air Cleaning Device (Jet Airflow Cleaning)

4. Jet Airflow + Brush Cleaning

5. Elastic Scraper Cleaning

6. Ultrasonic Technology Cleaning

Technical Parameters:

| Model | 600 | 950 | 1200 | 1400 | 1600 | 1700 | 2000 | 2100 | 2300 | 2600 | 2900 |

| Screen Area Per Layer | 0.28m2 | 0.72m2 | 1.10m2 | 1.50m2 | 1.80m2 | 2.30m2 | 2.60m2 | 3.40m2 | 3.90m2 | 5.30m2 | 6.40m2 |

| Net Site Area | 0.36m2 | 1.20m2 | 1.57m2 | 2.20m2 | 2.50m2 | 3.20m2 | 3.54m2 | 4.60m2 | 5.30m2 | 6.76m2 | 8.60m2 |

| Layers | 1, 2, 3, 4, 5 | 1, 2, 3, 4 | |||||||||

| Cleaning System | Options: rubber ball, brush, compressed air, brush and compressed air, ultrasonic, scraper | ||||||||||

| Motor Drive Power | 0.25KW | 1.5KW | 1.5KW | 2.2KW | 2.2KW | 4.0KW | 4.0KW | 4.0KW | 4.0KW | 5.5KW | 5.5KW |

| Height/Weight (mm/kg) | |||||||||||

| Single Layer | 758/132 | 987/350 | 1223/420 | 1359/810 | 1484/820 | 1371/900 | 1534/920 | 1441/1450 | 1450/1490 | 1774/1525 | 1488/1675 |

| 2 Layers | 837/142 | 1106/400 | 1381/480 | 1498/880 | 1642/890 | 1510/980 | 1692/990 | 1580/1530 | 1589/1575 | 1967/1660 | 1627/1790 |

| 3 Layers | 916/152 | 1225/450 | 1539/520 | 1637/950 | 1800/960 | 1649/1070 | 1850/1080 | 1719/1650 | 1728/1700 | 2160/1810 | 1766/1940 |

| 4 Layers | 995/162 | 1344/510 | 1697/590 | 1776/1030 | 1958/1040 | 1788/1140 | 2008/1150 | 1858/1760 | 1867/1825 | 2353/1960 | 1905/2090 |

| 5 Layers | 1074/172 | 1463/580 | 1855/660 | 1915/1110 | 2116/1120 | 1927/1220 | 2166/1230 | 1997/1890 | 2006/1975 | 2546/2130 | — |

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

Mobile Phone/WhatsApp/WeChat: 0086-15637361027