Overview:

Gyratory screen is also called Rotex gyratory screen, Rotex screen, Rotex vibrating screen, gyratory screener, gyratory separator, gyratory sifter, gyratory screening machine, planar rotary screen, plane rotary screen, rotary flat sieve, flat screen, square precision screening machine, reciprocating screen etc. Driven by an ordinary motor, this screening machine drives the eccentric wheel to do gyratory reciprocating motion. It is often used for screening petroleum coke, activated carbon, quartz sand, silica sand, frac sand, precoated sand, urea, fertilizer, resin, glass bead, wood pellet, sodium carbonate, melamine, tea, sugar, salt, soybean etc.

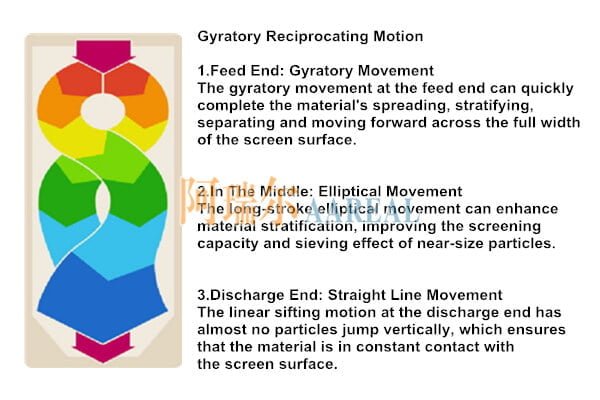

Working Principle:

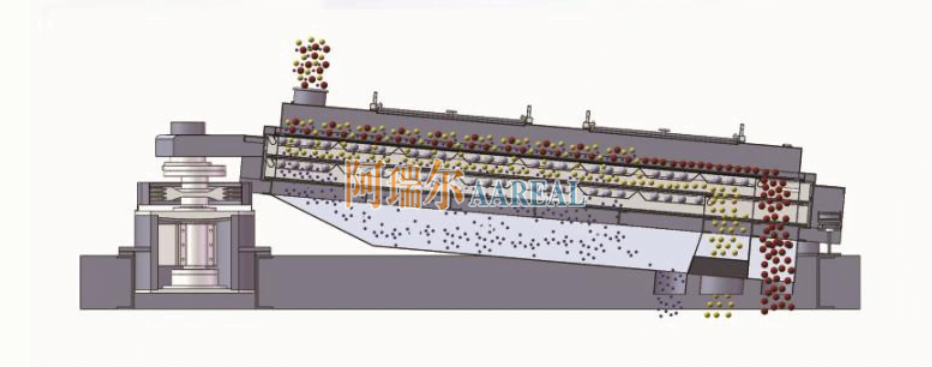

The gyratory reciprocating motion of Rotex gyratory screen begins with a circular motion at the feed end, gradually diminishing along the length of the machine to elliptical movement in the middle, and finally to an almost straight-line motion at the discharge end.

Technical Parameters:

| Layers | Model | Screen Surface Size (W*L) (mm) | Screen Box Stroke (mm) | Motor | Weight(kg) | |

| Power(kw) | Speed (rpm) | |||||

| 1 | 1014 | 1000*1400 | 63.5 | 1.5 | 960 | 715 |

| 1021 | 1000*2100 | 63.5 | 1.5 | 960 | 980 | |

| 1030 | 1000*3000 | 63.5 | 1.5 | 960 | 1200 | |

| 1521 | 1500*2100 | 63.5 | 1.5 | 960 | 1380 | |

| 1530 | 1500*3000 | 76 | 2.2 | 960 | 1340 | |

| 1536 | 1500*3600 | 76 | 5.5 | 960 | 2410 | |

| 2 | 1236 | 1200*3600 | 76 | 5.5 | 960 | 2020 |

| 1021 | 1000*2100 | 63.5 | 1.5 | 960 | 1400 | |

| 1030 | 1000*3000 | 76 | 4 | 960 | 1840 | |

| 1521 | 1500*2100 | 63.5 | 4 | 960 | 1710 | |

| 1836 | 1800*3600 | 76 | 7.5 | 960 | 3880 | |

| 1530 | 1500*3000 | 76 | 7.5 | 960 | 2780 | |

| 1536 | 1500*3600 | 76 | 7.5 | 960 | 3180 | |

| 3 | 1021 | 1000*2100 | 63.5 | 5.5 | 960 | 2150 |

| 1530 | 1500*3000 | 76 | 5.5 | 960 | 3200 | |

| 1836 | 1800*3600 | 76 | 7.5 | 960 | 4170 | |

| 2050 | 2000*5000 | 92 | 11 | 960 | 5500 | |

Advantages:

1. unique gyratory reciprocating motion

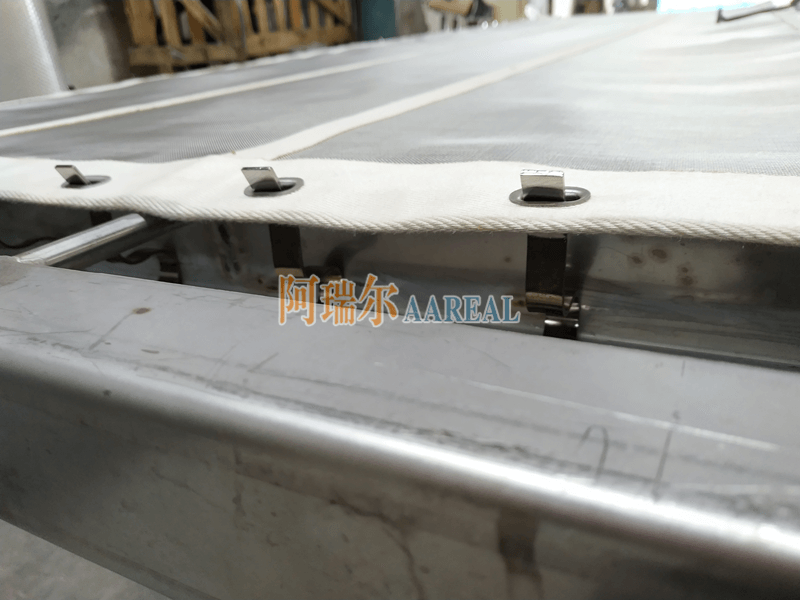

2. automatic screen surface tension device

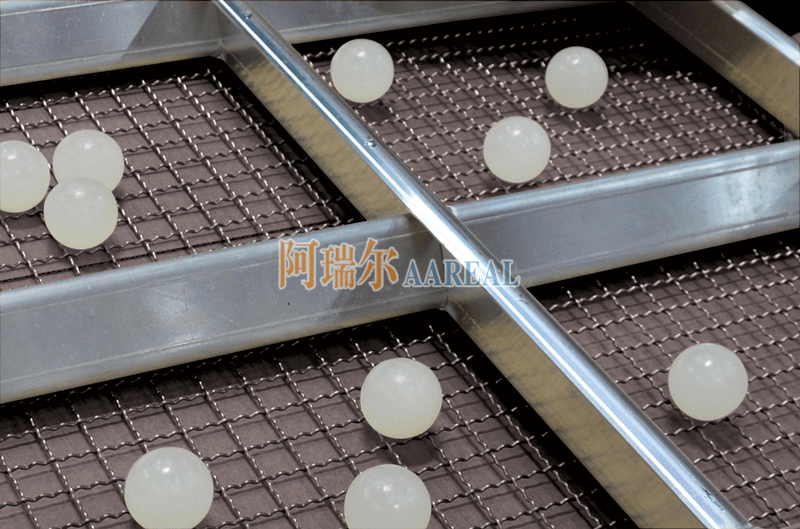

3. ball cleaning system

4. double-balanced motor system

5. convenient and quick compensating clamps for head cover

Features:

1.Super large capacity and high screening accuracy, suitable for industrial continuous screening.

2.The effect of anti-clogging screen mesh blinding is good. Especially suitable for the screening of materials which are easy plugging and sticking the screen mesh.

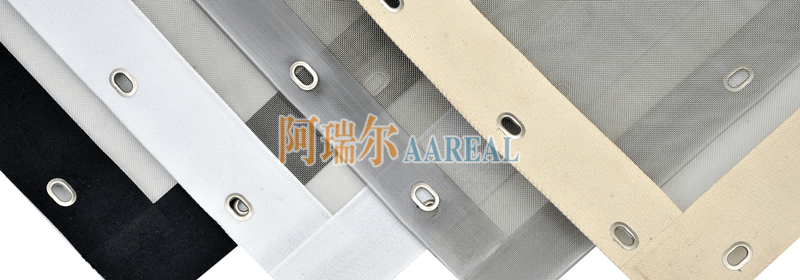

3.Screen service life is long. It is 5~100 times than the ordinary vibrating screen.

4.The soft running does not damage the particles original structure of the material.

5.Three types of screen tensioning spring clips and screen side-pull mode. Easy to remove and replace the screen.

6.It is not easy to generate static electricity, especially suitable for the screening of materials those are flammable and explosive, and easy to generate static electricity.

7.Smooth operation, no special requirement for the plant.

8.Totally enclosed structure, no dust, low noise to 70 decibels.

Mesh Screen

Mesh Cleaning Balls

Compensating Clamps

Automatically Tensioned Screens

Metal Screen Frame, Sturdy and Durable

Installation:

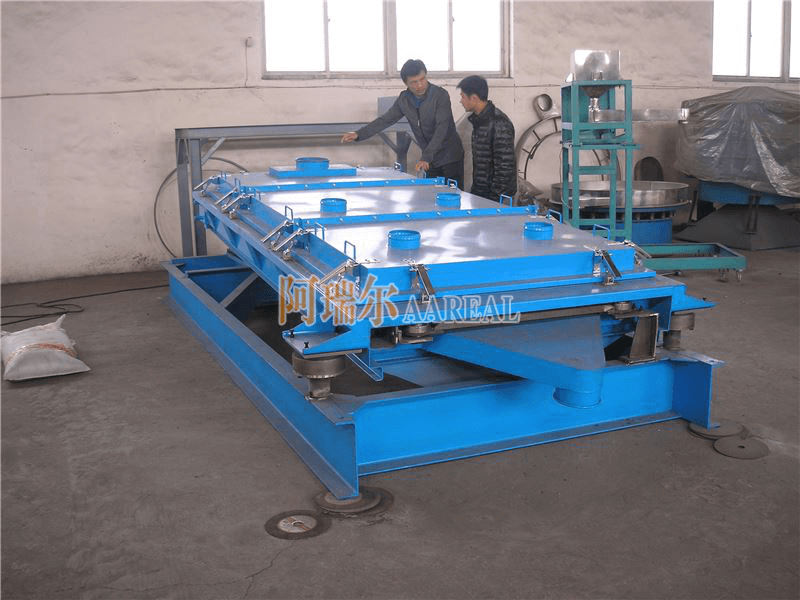

1. Seat Installation:

Forward Type

Direct Discharge Type

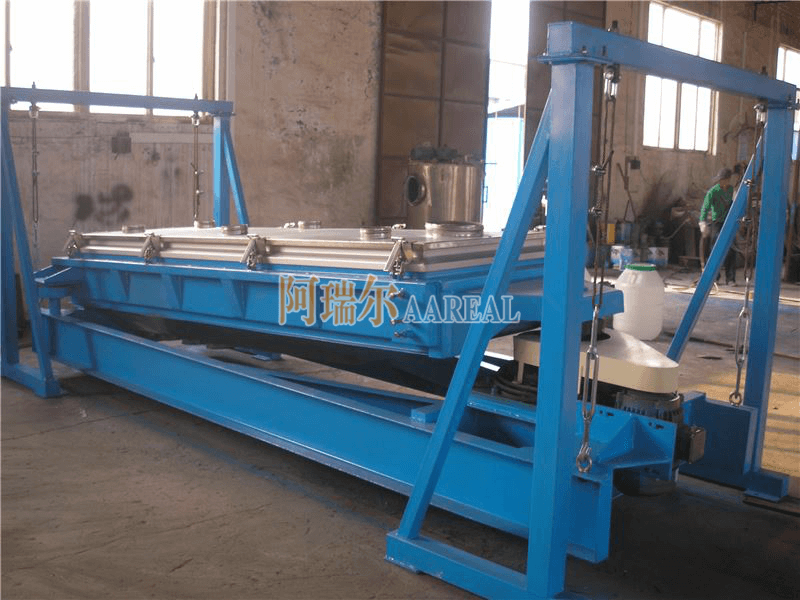

2. Cable Suspension Installation:

Suspension Type

Application:

Abrasive: glass beads, slag, alumina, sand and other abrasive materials

Animal feed: feed powder and chips, meat paste and small food

Carbon products: coking coal, graphite, charcoal etc.

Chemical products: hundreds of different compounds

Clay: product classification

Fertilizer: raw material sieving and finished product fine screening.

Including ammonium nitrate, phosphate, potassium hydroxide, urea and other compounds

Food: sugar, flour, milk powder, coffee, cereals, rice, nuts, condiments, cocoa powder, glucose, starch etc.

Grain cleaning: corn, wheat, soybean and other cereals peeling and cleaning

Ore: ore, rubble, limestone, soda ash and salt

Paper: paper pulp, coating

Fiberboard: wood chips, flaking, bits of wood, to make high quality fiberboard

Drug: many large drug manufacturers use our screening machines, which meet the health standard design and GMP, to achieve precise and effectiveseparation and cleaning

Plastic: plastic particles, plastic powder

Powder metal: aluminum, copper, iron, nickel, steel, zinc and many other metal powders

Recycling of resources: used in the recycling of various materials, such as PET recycling etc.

Steel-making: classification of steel shot and metal filing

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

Mobile Phone/WhatsApp/WeChat: 0086-15637361027