How many screen frames or screen structures for linear vibrating screen? Let’s learn the classification and characteristics of Screen Frame Grid Structure of Linear Vibrating Sieve now.

I) Wooden screen frame:

This kind of screen frame is generally made of high-quality poplar wood, red pine wood and white pine wood as raw materials. Due to the use of wooden raw materials, the cost is greatly reduced compared with the cost of the hook plate (or hook screen), and it is more durable. However, if the wooden screen frame is used for a long time, some wood chips will fall. Once the wood chips are mixed with the user’s raw materials, it will seriously affect the quality of the user’s screening material. And if the screening capacity is too large, a linear vibrating screen may appear fracture of the screen frame.

General users will choose wooden grids for the following reasons: 1. cost saving; 2. easy to replace the screen; 3. bouncing balls can be added to increase the passing rate. Common wooden screen frame materials include red pine screen frame, white pine screen frame, and poplar screen frame. The cost of poplar screen frame is lower, and the price is about 3 times lower than the other kinds of screen frames.

Wooden Screen Frame

The advantages of wooden grids or wooden screen frame are as follows:

1. Cost advantage: The use of wooden grids for linear vibrating screens will greatly reduce manufacturing costs. Compared with the steel or iron frame grid, the manufacturing cost can be reduced by 10%. As far as small and medium-sized users are concerned, the saving of procurement costs is the increase of gross production value;

2. Maintenance advantages: The wooden screen frame has great advantages in subsequent maintenance. Because it is made of high-quality wood and is durable, users can rest assured, and subsequent maintenance and replacement are even easier. Due to the previous advantage, you can consider storing more sets of net racks, and when you need to replace them, you can directly replace the whole set of screen frame to ensure the efficiency of production.

3. Advantages of screening effect: the use of wooden grids does not affect the characteristics of the materials, and does not affect the quality of the materials during the screening process. Due to the characteristics of some materials, the use of iron grids will affect the characteristics of the materials.

The disadvantage of the wooden screen frame of linear vibrating screen is that if the wooden grid is used for a long time, some wood chips will be dropped. Once the wood chips are mixed with the user’s raw materials, it will seriously affect the quality of the user’s screening materials.

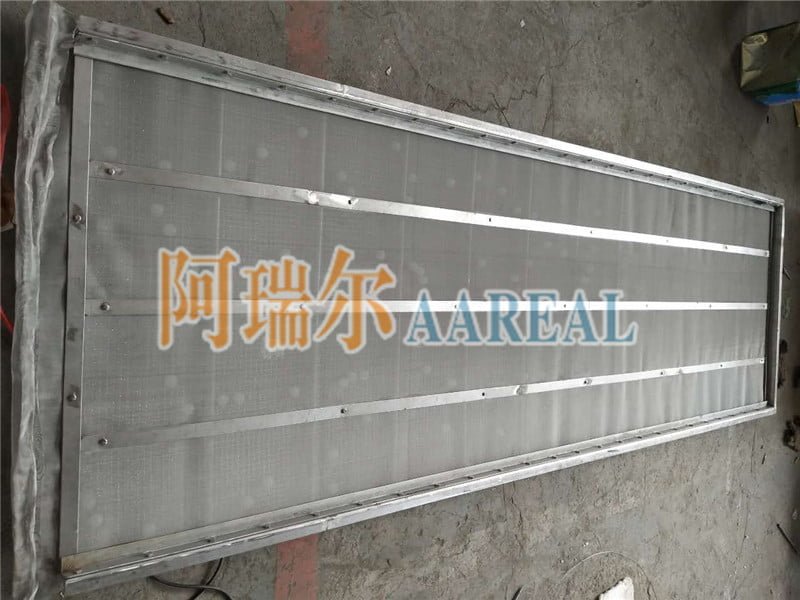

II) Metal screen frame:

The metal screen frame of the linear vibrating screen is also called the hook-plate screen frame structure or hook screen. Its material can be divided into Q235 carbon steel and stainless steel 304 etc.

Carbon steel screen frame: It is made of Q235 or Q345 material and connected by bolt compression. It is mainly used to fix coarse wire screens. It is mainly used to screen ore materials and materials with higher strength. It has strong wear resistance and large load-bearing capacity, which is very suitable for large-capacity of light linear vibrating screens. It can be used to screen large particles and materials with heavier specific gravity. The disadvantage of this screen frame is that the cost is higher than that of the wooden screen frame, and it is more troublesome to replace the screen.

Stainless steel screen frame: made of stainless steel 304 or 316L and other materials, generally used in chemical, food and other places with strong corrosiveness or strict hygiene requirements, but the price will be more expensive than carbon steel.

Carbon Steel or Stainless Steel Screen Frame

III) End-tension screen structure:

The end-tension screen structure of linear vibrating screen is to tighten the screen back and forth, and finally fix it by bolts, without a bouncing ball cleaning device. The material screening rate of a single screen is high and it is convenient to replace the screen.

End-tension Screen

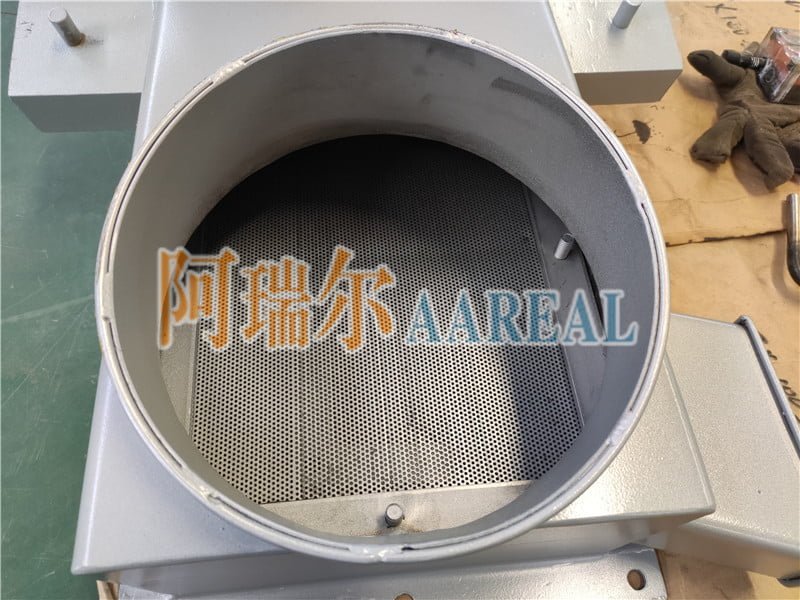

IV) Perforated sieve plate:

This kind of grid can no longer be called a screen frame in a subjective sense. It is formed by punching a whole steel plate through a punching machine at one time. Its advantages are sturdiness and durability, strong bearing capacity, and easy replacement. It is mostly used for screening large pieces of materials. But its shortcomings are also obvious. The cost is higher because the whole sheet is punched.

Perforated Sieve Plate

Our company produces all kinds of linear vibrating screen machines, such as 500*2000 mm, 500*2500 mm, 1000*2000 mm, 1000*2500 mm,1000*3000 mm,1000*4000 mm, 1200*2500 mm, 1200*3500 mm, 1200*4000 mm, 1500*3500 mm etc, 1~6 layers. We can choose the appropriate linear vibrating screen screen frame structure for you according to the different screening materials of customers and the requirements of screening efficiency. Welcome to send RFQs.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

Mobile Phone/WhatsApp: 0086-15637361027