How does the Ultrasonic Screen stick to the screen frame?

The ultrasonic vibrating screen generally adopts the adhesive type of Screen Frame or Screen Holder)....

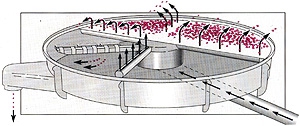

Overview of Tumbler Screen Machine Special for Xylitol:

Tumbler Screen Machine Special for Xylitol is used for the large-capacity fine screening of 25 μm~1mm powder, which is comparable to German screening technology. The swinging sieve equipment is applicable to chemical industry, food and spices, plastics and synthetic resin, mining, medicine, wood, metallurgy, feed, fertilizer, firework etc.

600mm Tumbling Screen Machine

Contact Part Stainless Steel Tumbler Screener with Quick-open Clamps

Contact Part Stainless Steel Swinging Sieve with Cylinder

Carbon Steel Tumbler Screen Machine

Features of Tumbler Screen Machine Special for Xylitol:

1. Simulate the action of manual screening. Particles are rolling and spiral involute. The screening accuracy is as high as 90-99.9%.

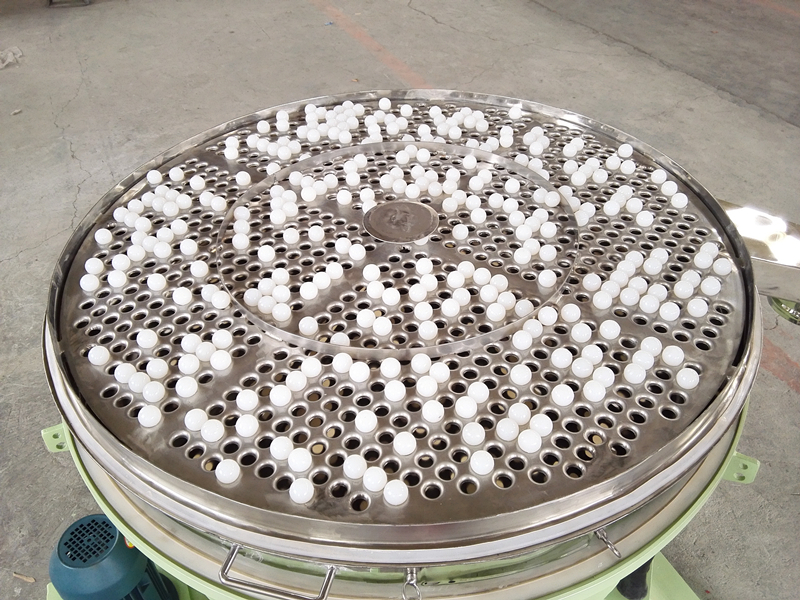

2. A variety of anti-blocking mesh technology (bouncing balls, rolling brush, air-brush, elastic scrape, ultrasonic etc.) ensure the continuity of screening.

3. It can be used up to 7 layers for 8 particle sizes.

4. The soft screening action does not damage the particle structure of the material.

5. It is not easy to generate static electricity. Suitable for screening flammable, explosive and electrostatic materials.

6. Completely balanced. Super long operating time without failure.

7. Large sieve machine is equipped with cylinder lifting device, which is more convenient to replace the screen.

8. Circular block structure, simple disassembly, fully enclosed, more environmentally friendly.

9. The screen structure is diverse. It can be spliced together and also can be bonded as a whole.

10. The outlet can be rotated 360 degrees at will. And the noise is as low as 75dBa.

Brush for Mesh Cleaning

Air-brush for Mesh Cleaning

Bouncing Balls for Cleaning Mesh

Locking Force Marker

Splicing Screen

Rubber Tension Spring

Technical Parameters of Tumbler Screen Machine Special for Xylitol:

| Model | 600 | 1000 | 1200 | 1500 | 1800 | 2000 | 2300 | 2600 | 2900 |

| Screening Area (m²) | 0.28 | 0.72 | 1.10 | 1.80 | 2.30 | 2.30 | 3.90 | 5.30 | 6.40 |

| Layers of Screen | 1~5 | 1~5 | 1~5 | 1~5 | 1~5 | 1~5 | 1~5 | 1~5 | 1~5 |

| Power | 0.25 | 1.5 | 1.5 | 2.2 | 4.0 | 4.0 | 4.0 | 5.5 | 5.5 |

Mesh Cleaning System: rubber ball, brush, compressed air, brush and compressed air, ultrasonic, scraper etc.

AAREAL is a factory which specially produce the vibrating screen machine, such as kaolin rotary vibrating sieve machine, metal powder ultrasonic vibrating screen, flour flow-thru separator, PVC powder inline vibrating screen, food additives tumbler screening machine, calcium carbonate linear vibrating screen, quartz sand gyratory screen machine, silicon metal powder gyratory sifter, herbal powder centrifugal airflow screen etc.